When trust translates into major construction projects: PERU

Our experience in this field, which is backed by emblematic projects such as the Antamina Mine, Toromocho, Toquepala, Cerro Verde, the Talara Refinery and the Pluspetrol Plant, confirms our commitment to quality equipment, safe solutions and constant technical training.

These types of projects can only be carried out with a team committed to comprehensive service, ranging from the pre-sales phase, where we offer advice, to support during installation and after-sales maintenance. Our team of engineers and formworkers on the jobsite ensure that each project is carried out efficiently and maintained in optimum condition.

MARCO ASENCIO “Our success is based on the quality and reliability of our products”. |

In mining and industrial maintenance, speed is crucial. During plant shutdowns, equipment must be available almost immediately, with materials and training having been planned in advance. Success is based on the quality and reliability of the materials, effective solutions and constant technical training for the assembly of BRIO scaffolding. The presence of warehouses throughout the country makes it easier for us to provide a quick response to customers. Customers prioritise the optimisation of operations, and seek equipment such as the BRIO system, which guarantees durability and easy maintenance. Safety is paramount; therefore, there is a demand for solutions that exceed safety regulations, such as those offered by ULMA Construction. The essential needs of the sector are complemented by sustainability and an agile and personalised customer service. The flagship product in this area is BRIO scaffolding. It stands out in the industrial sector for its certified safety and high quality design, indispensable in hazardous environments. Its flexibility adapts to all types of projects and geometries, with efficient assembly and dismantling that saves time and costs. BRIO’s durability ensures optimal performance, even under extreme conditions, contributing to reduced operating and safety costs. DIGITALISATION IS MAKING A DIFFERENCE

|

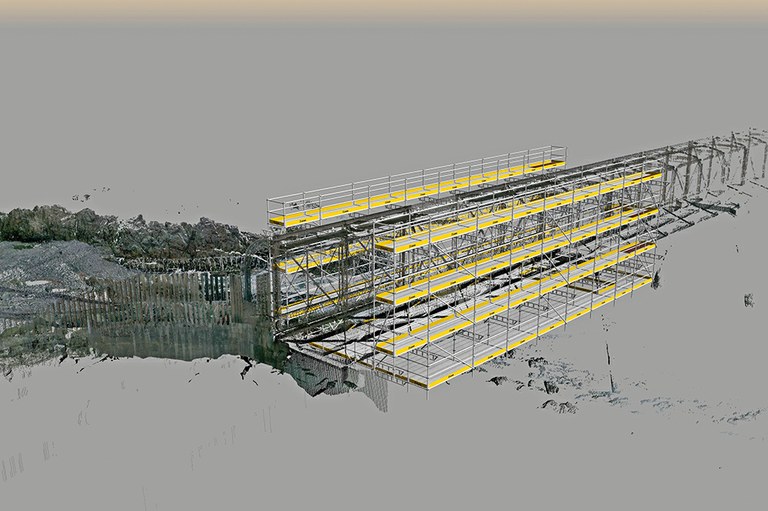

CERRO VERDE MINEPLANT SHUTDOWN IN MILL AREA Cerro Verde is an open pit mine at an altitude of 2,600 m and one of the main producers of copper in the country. The maintenance and rehabilitation of equipment and infrastructure in the mine calls for a process and a product that allows all the work to be carried out in a very short timeframes. During the 2023 plant shutdown, since there were no up-to-date drawings, the team used the laser scanner to reproduce the structures in order to optimise the application, modulation and solutions using BRIO scaffolding. This technology, together with our expertise in project management, was reflected in accurate drawings and materials for structures such as suspended scaffolding, working platforms and fixed towers, resulting in significant savings in resources. Compared to the traditional methodology, delivery time was reduced by 25% and tonnage delivered by 15%, thus reducing equipment, transport and assembly costs. The close cooperation with the customer and the logistical and commercial management team resulted in a service that exceeded expectations, with a total of 60 tonnes delivered. ILO FOUNDRYORE DOCK The Southern Cooper Corporation mining company requested a BRIO scaffolding solution to carry out maintenance work on its ore dock. One of the requirements was to be able to work in a BIM environment that would allow the establishment of standard solutions that could be used by the customer in current and future maintenance work. The initial difficulty was the lack of up-to-date original plans of the structure on which we had to work. Together with our BIM expertise and Revit® software, we performed a 3D scan of the environment which allowed us to model the structure and develop an optimised suspended scaffolding solution in a reduced timeframe. The result has been a 3D model, capable of being integrated into the customer’s BIM environment, with plans accessible via QR codes from any device, and which will facilitate future maintenance tasks |

OSWALDO PICÓN Jefe de andamios “Scanning reduces equipment, transport and assembly costs”. “Scanning provided us with a highly accurate digital representation” |