Smart products: latest technology to offer the best service to customers

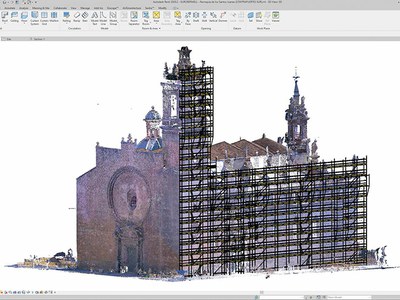

We have added laser scanning to our scaffolding libraries in REVIT and to the Scaffmax® configurator. The digitalisation of working processes represents a breakthrough in accuracy and productivity. Therefore, laser scanning is an effective tool to consider when using scaffolding.

With our laser scanning system we achieve:

GREATER ACCURACY AND SAFETY:

With a single scan, we obtain an exact replica of the building, at any height and distance. So, the scaffolding used and the materials sent to the site fit together right away. We can forget about making changes during the process.

SPEED AND ACCESSIBILITY:

In a short period of time and with fewer resources, it collects millions of bits of data per second; a point cloud is created from the measurements, depicting an accurate 3D model of the building or structure. A major digital development from 2D drawings on paper - which limit what you can read - to 3D models that provide all views. And everyone involved in the project can access this virtual model, which is extremely useful for coordination tasks.

LOWER COSTS:

This accuracy leads to a more effective scaffolding application study. The improvement in terms of logistical organisation and calculating the supply of necessary materials will make it possible to cut costs, increase productivity, and reduce the time on taking measurements.