Description

Within the National Railway Plan, the 80-km Évora-Elvas line will become the first high-speed section of a line in Portugal, used to transport freight and passengers.

This section is part of a wider project, called the Southern International Corridor, which will connect Elvas to the port of Sines, improving the country's links to Europe.

In these works managed by the state-owned company ‘Infraestruturas de Portugal’, we were involved in four of the five sections, partnering with construction companies such as MotaEngil, MADONU, Constructora São José, Teixeira Duarte, Sacyr, COMSA, Fergrupo y FCM.

- Freixo - Alandroal section: 20.5 km

- Évora North – Freixo section: 20.5 km

- Évora – Évora North section: 10 km

- Alandroal – Leste line section: 38.5 km

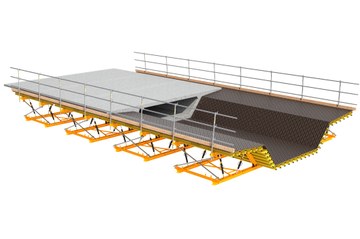

ULMA Solution

The Freixo - Alandroal section has 10 viaducts and 16 overpasses. In addition to supplying a large amount of equipment, performance went hand in hand with safety. For the construction of the respective decks, we supplied 20,000 m³ of the OC shoring system and around 4,000 m² of ENKOFORM formwork. We installed 3,600 m² of ORMA formwork and 10 sets of formwork for columns and footings, combining ENKOFORM and ORMA, as well as 280 metres of stairs and 10,500 m² of BRIO scaffolding.

The scale of this project has involved the supply of tonnes of equipment, engineering solutions, and continuous communication between all those involved in the project.

Gonçalo Gonçalves, Project Manager at MotaEngil: “In such a complex project, ULMA's team has been highly effective in its responsiveness, supply of equipment, engineering solutions and technical support. Additionally, not only did they ensure that the deadlines were met, they did so safely. This is a company that we can trust, which supports us throughout the project”.

In the Alandroal – Leste line section we provided shoring and formwork systems for three viaducts, 10 underpasses, and wall formwork for 13 viaducts: 25,000 m³ of T-500 shoring systems, climbing brackets and profiles, around 1,000 m² of ENKOFORM formwork and 3,800 m² of ORMA formwork.

João Castro, Project Manager at Madonu Grupo: "ULMA has a highly professional team that supports us in on-site studies, assembly and management, throughout the process and the project. Above all, the solutions that they recommended are cost-effective. They allow us to work safely and to reuse the equipment on the different viaducts that we are going to construct".