Description

Due to the project’s location in a deep valley, ULMA proposed that the deck be executed using the balanced cantilever method. This technology is a highly efficient to build large-span bridges whenever the piers are especially tall or the terrain makes shoring from the ground too complex.

The ES-60 Viaduct comprises two carriageways of 186.8 m each. The left hand side, toward Szczecin, is 13.7 m wide, while the right measures 15.15 m. The deck is divided into three spans, two of which measure 50.9 m in length, while the third is 85 m. It varies in thickness from 4.22 m at the central piers to 2.5 m at the extremes. The deck was executed in sections of differing dimensions, according to the construction system used: the pier segments of 11 m in length, the end segments of 2 m, and the abutments of 9.4 m, while the sections poured using the balanced cantilever method were 4 m each, with 7-day work cycles.

ULMA Solution

Various ULMA formwork systems were used in the construction of the ES-60 Viaduct. The foundations, abutments, and central piers were built using the ORMA Wall Formwork system. The first pour was 6.6 m while the following pours, ascending upward with BMK Climbing Brackets, were 3.2 m.

The pier segments reaching 11 m in length were poured on piers measuring 22.6 m and 20 m in height, respectively. In order to do so, a grid-work of DIPE450 and IPN500 steel beams were supported by the piers so that tall shoring systems were unnecessary. HMK Bridge Deck Formwork was used for the base and sides of the box-girder deck, due to its ability to adapt to varied geometry.

Throughout the entire construction process, all working spaces, including foundations, abutments, piers, and pier segments, were protected with MBP Mesh Guardrails. Access to the pier segments was provided by BRIO Stairways anchored to the piers themselves.

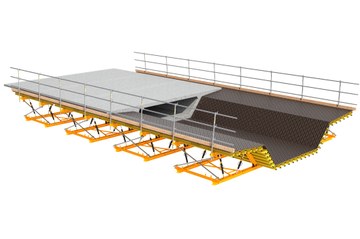

Four separate CVS Formwork Carriers were used to build the deck. The left carriageway, 13.7m wide, was built first, followed by the right, 15.15 m in width, for which the same carriers were reused with only slight modifications necessary. CVS Carriers are made of two principle load-bearing frames, latticed together with MK Trusses. These structures are used to hang both the upper and lower slab foundation formwork structures. A BRIO platform was installed at the front of the carrier to perform pre-tensioning procedures, as well as providing access and communication between platforms. The entire carrier is operated with hydraulic equipment, which lifts, levels, and advances the carrier as needed.