Description

The new Sagrera Station is the most important infrastructure development to be built in Barcelona since the Olympic Games. The station will be the largest building in the city and the second largest in the metropolitan area, after T1 at El Prat Airport, and will be the biggest urban transformation the city has seen in recent decades.

The station is being built on a surface area of 295,000 m² reaching up from underground with an exchange on four levels where high-speed (Spanish AVE and French TGV), long and medium distance, and suburban trains, along with the metro and intercity bus services will all converge. All levels will be joined by a large connective courtyard.

ULMA solution

ULMA has participated since the beginning of the project with comprehensive solutions for the execution of the in-situ concrete structures of this railway station. Though it is a complex project with different load requirements in each phase, ULMA products proved sufficiently versatile to provide the solutions needed throughout.

In spite of being a very repetitive structure, not all the elements are the same, so ad hoc solutions had to be implemented. In addition, the structure is mixed, with prefabricated and in-situ elements, so that in the shoring areas the loads are variable.

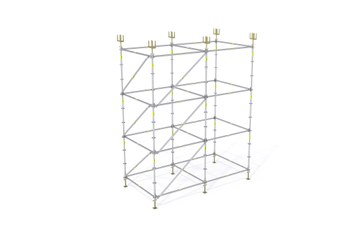

VR Tables with braced ALUPROP props were designed to execute the slab-beams, since the geometries are regular in terms of dimensions and distances between columns. This technical solution, used for the high-speed line storey, made it possible to decrease cycle times since the table can be moved as a single unit, without having to be disassembled and reassembled. In those sections where it was not possible to use the table system, the BRIO shoring system and ENKOFLEX formwork were combined, given the flexibility of both products to adapt to different geometries and heights, and the ability of the products to provide many levels of safety. In fact, with the perimeter safety system for the formwork, combined with the MBP mesh guardrail, up to 1.72 m in height was covered in the construction of the 2.1 m high beams.

For the execution of the 1.15 m thick slab, due to the slab thickness and the volume of equipment that had to be supplied, the solution designed was a combination of the robust OC shoring system and ENKOFORM H-120 formwork. In those cases where the slab thickness was smaller, T-60 shoring with ENKOFLEX formwork was used, to avoid excessive gang size.

A combination of ORMA formwork and the UCAB-EUC single-sided truss system was used for the 36,000 m² foundation slab with a height of 4 m.

ULMA's team is present at the construction site on a daily basis. This allows us to have a high degree of closeness and communication with the client, which is fundamental to providing the resources needed within the deadlines required.