Atlantic Station Mixed-Use Development, U.S.A.

The Atlantic Station Project will transform the old Stamford, CT Post Office building into a mixed-use development with spectacular views of Manhattan and Long Island. The complex comprises a dynamic retail and restaurant area set underneath two tower blocks reaching 21 and 29 storeys tall, respectively, as well as a car park for more than 800 vehicles.

Formwork and Scaffolding ULMA for the largest Water Treatment Plant in all of Central Europe

The new water treatment plant in Prague is the biggest project in the Czech Republic currently underway, and when completed will be the largest facility of its kind in all of Central Europe.

ULMA offers flexible solutions for Dubai City Walk Project

ULMA has offered rapid, simple, and, most importantly, flexible solutions for this project composed of extremely diverse slab thicknesses and heights.

Formwork technology for the incremental launching method for two bridges in Poland

Within the frames of road investments planned in Poland to the year 2020 the number of bridge-type works made with the use of the incremental launching method has substantially increased. ULMA has recently undertaken the design and delivery of a special formwork which allows applying the incremental launching technology to construct two bridges: MS-6 viaduct on the S5 road and the E-1 Bridge on the S19 road, located in Poland.

ULMA Formworks for special geometry piers

The versatility of the formwork structures provided a solution both profitable for our client and efficient for the construction of the octagonal piers required in Mexico – Toluca Intercity Train project.

Innovative Solutions of formwork in Avant-Garde Architecture

The Fondazione Prada Museum, designed by the architect Rem Koolhaas, attempts to integrate traditional and avant-garde architecture in a single space.

Discover the Many Faces of ULMA in Our New Corporate Video

This video represents the latest development in ULMA media communications, following closely behind the publication of Construction Book. With compelling audiovisuals and illustrative graphics, both productions convey our identity, our values, and our way of working.

ULMA Comprehensive solutions in Venda Nova III dam, Portugal

When more than 2,000 t of material is mobilised, when extremely versatile construction systems are needed, and when the speed and simplicity of assembly is crucial, experience is absolutely fundamental to success.

ULMA takes part in the construction of Ichma Tower in Peru by means of solutions that empowers modernity, efficiency and the sustainability of the building

In an area that houses the country’s principal business and financial headquarters, this new tower is built to LEED Green Building certification standards for greenhouse gas emissions and efficient resource use. From the second to the thirteenth floors there will be four offices per storey, and from the fourteenth to the twentieth, only two.

ULMA Updates its Image with a New General Catalogue and New Products on Display in the Showroom

ULMA presents its new general catalogue, Construction Book, with more than 250 pages featuring extensive information covering the entire product portfolio, including formwork, scaffolding, and bracing systems, along with descriptions of more than 70 projects executed around the world. The publication of this document coincides with a comprehensive update of the systems exhibited in the Showroom. All of our latest product developments are already on display so that the customer can get to know the latest market releases first hand.

Transforming the metropolis of São Paulo

The impending Olympic Games in Brazil are transforming the metropolis of Sao Paulo, with marked effects on the city's road network. In the southern part of the city, the “Chucri Zaidan” urban plan includes various real estate developments, as well as infrastructural projects providing roadway, environmental, and social improvements. As part of this plan, two new bridges – Laguna and Itapaiuna – were built in the district of Marginal Pinheiros, and ULMA took part in both projects. With an investment of R$305 million, the bridges will greatly ease traffic both to and from this historically congested area.

Safety, Ergonomics and Innovation: The perfect equation that translates into high-performance solutions on site

ULMA accompanies each client from the start of every project until its final construction, studying the options for each site, designing the technical solution for formwork and scaffolding and providing the most suitable construction material, together with the safety systems that help to prevent possible incidents during the construction on site.

The Key to Innovation: Close Customer Relations

Every year we develop new and improved products, the quality of which clearly demonstrates the effectiveness of close collaboration with our customers. This is the way to remain on the cutting edge of research, creating ever-more advanced and efficient scaffolding and formwork systems, tailored to both customer and market requirements.

ULMA systems at Ammonia and Urea Plant in Bolivia

The commencement of operations for this project will meet the entirety of domestic demand, wholly supplanting imported fertilizers. The plant is anticipated to produce 756,000 tonnes annually. Twenty per cent of production will be for internal markets, and 80% for export. The products made from these raw materials will improve crops, increase soil productivity, and recuperate depleted land.

New SBU Safety Platform designed to work with wall formwork

ULMA Construction designed the new SBU Safety Platform to provide an optimally efficient, versatile and safe building solution, allowing our customers to work with wall formwork at any height in complete and guaranteed safety.

Estaiada Bridge, Line 4 of Metro,RJ, Brazil

As part of the infrastructural improvements planned for the 2016 Olympic Games, Line 4 of the Rio de Janeiro Metro will extend 16 km to connect the city from west to south. In addition to relieving traffic congestion, the metro will be capable of transporting 300,000 passengers daily and will reduce their transit time from 2 hours to just 15 minutes. Never before has a self-climbing system been used to build inclined pylons for a cable-stayed bridge in Latin America.

BIRAMAX: Innovation in Circular Formwork

BIRAMAX represents the latest innovation in circular formwork, designed with all the hallmarks of a new ULMA product: ease of use, flexibility, and complete system modularity.

108 m Pylon Constructed with Self-Climbing System

It is part of a bridge that will be the longest structure of its kind in the region of Podkarpacie.

Fast progress with CVS formwork carriages

The El Aserradero viaduct, in Colombia, is one of the most complicated structures on the 13.1 kilometre stretch of the “Segunda Calzada Primavera - Camilo C”.

Big solutions, big projects

With an annual production capacity of 1.6 million tons of cement, the new plant based in Piura will be the most modern in Latin America.

MK System: cost-effective, flexible and modular

The Tintenbar-Ewingsdale stretch of the Pacific highway is 17 km long. The project’s main objectives are to improve road safety, achieve uninterrupted traffic flow and provide access to the highway from nearby towns.

Full performance self-climbing systems

One of the highest skyscrapers in Poland, the Q22 tower is rising in the centre of the Polish capital. At 155 m high, this office building will have 47 floors, 5 of which will be underground.

Crossing Bay of Cadiz

In Bay of Cadiz Bridge in Spain with high load-bearing shoring, large scale carriers and challenging technical requirements, ULMA shows its response capacity with regard to logistics, available material stock and quick, flexible and highly skilled technical assistance.

Energy projects in Peru

ULMA has many years of experience, a wide scope of expertise in this area and has carried out a considerable number of projects in Peru.

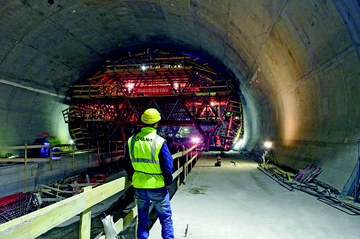

MK mine tunnel carriages

Flexible and cost-effective solution with a standard product. MK System applications are multiplied.

Gantry false work on heavy-duty MK shoring towers for the load-carrying structure

The two-lane, seventeen span and almost 950 meters long ES 5.5 overpass was built within the S-8 expressway in Poland, between the Walichnowy and the Wrocław junctions. Its load carrying structure consists of a prestressed box, divided into four segments with expansion joints.

ULMA Showroom - 1,700 sq metres of product and experience

The Showroom is ULMA's shop window for products, capabilities and a place for training and learning.

ULMA & ATTIEH alliance: interview with Nouri A. Daher

Nouri A. Daher, General Director of ULMA ATTIEH is now working for 6 years side by side with ULMA. The fruits of this partnership are large projects such as the Briman Project, Damman Project, etc.

ULMA launches the most optimised light formwork solution into the market

The light LGW formwork is the result of turning research and innovation into new products, new solutions and new services for the customer.