Description

El proyecto consiste en la construcción de un túnel a cielo abierto, así como las instalaciones y servicios en la vía A3. La longitud del túnel es de 655 m, y la anchura de 45 m con los tres huecos. El hueco central está destinado al tráfico ferroviario con dos líneas en cada dirección. Este proyecto ha requerido 300.000 m³ de hormigón.

ULMA solution

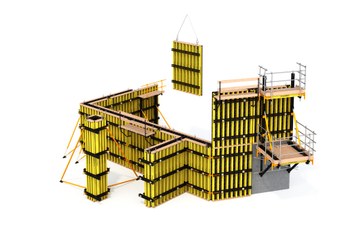

The ULMA & DELMON team provisioned formwork for the walls and slabs of the central tube, measuring 20 m in width, as well as the lateral tubes, each of which are 13 m wide. The walls are 2 m thick at the base, and thin to 1 m at the highest point of 13 m. The ceiling slab, 1.8 m thick, was built to be straight though slightly inclined, throughout almost the entire length of the tunnel.

The client required that all tunnel sidewalls, even for those reaching 13m tall, be executed in a single pour. At these heights the fresh concrete can exert enormous pressure on the formwork, and with more than 3.6 km of sidewall to pour, the solution had to be robust yet quick to install and easy to use. Components of the beam formwork system ENKOFORM V-100 were used to withstand all of the pouring pressure required. In fact, the simplicity of the system provided a level of productivity that exceeded customer expectations.

The ceiling slab measuring, 30,000 m2 with a thickness of 1.8 m, was built at a height of 9 m aboveground. The T-60 Shoring Towersproved ideal for this situation. The towers were combined with a pre-assembled table formwork system transported by bogie to save both time and work.

With our client’s requirements at the forefront, the solution that provided savings in the set-up and take-down for every pour. This is what made the difference in the customer’s choice of ULMA & DELMON for their project, and the final results were no less rewarding than initially promised.