Description

This is a cut-and-cover tunnel (115 m) in the EN-101 Bypass Ponte da Barca - Arcos de Valdevez, in Portugal.

ULMA Solution

ENKOFORM HMK and ENKOFORM V-100 beam-based formwork was used in tiers of 12 m except for the first and last which was 9.5 m.

The cut-and-cover tunnel was completed in two pouring stages: side walls and vault.

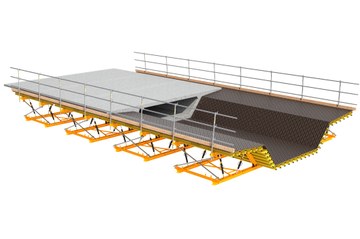

The side walls were built with double-sided ENKOFORM V-100 formwork consisting of steel walers and timber beams. The side walls were shaped with curved walers, while DW15 tie rods bore the concrete pressure. The outside waler was anchored to the foundation and had a level of built-in working platforms for pouring work. The inside waler was also anchored to the concrete of the counter-vault and kept stiff with push-pull props. Inside and outside formwork units had a level of built-in working platforms. Both units were moved by crane using lifting hooks.

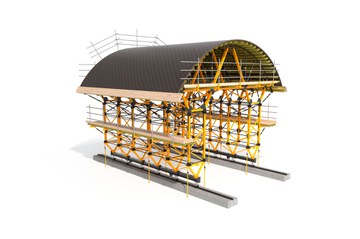

For the vault of the cut-and-cover tunnel, the inside formwork was placed on a vertical formwork carrier moving on rails. The form carrier consists in a structure of MK walers. It has working platforms at several levels with handrails of 1.5 m and safe access.

In vault areas where double-sided formwork was required, a crane-handled outside formwork joined to a working platform was used. The working platform consisted of ORMA brackets to plumb the outside formwork unit.