Description

With an approximate production capacity of 1,100 tons per day, the aim of this new plant is to produce 40% of the company's cement, as well as to supply the domestic demand and exports for the USA and Europe.

ULMA Solution

Aside from the difficulties of a construction project of this type (2,700 tons of steel, 30,000 m2 of formwork and 20,000 m3 of concrete), it was necessary to add new challenges, such as the complexity of the structures, the orography, and the short execution times.

The vertical structure of one of the industrial buildings exceeded 110 meters in height, for which T-60 shoring towers were used. These are designed for considerable height applications, as well as for large slabs shoring. The slabs were executed with BTM beam formwork.

Due to the product characteristics, it was possible to optimize the shoring and formwork solution, in addition to supplying the amount of material (650 tons) in the agreed project time-frame.

The COMAIN Handset Formwork is the ideal system for any type of work in which it is necessary to obtain a good finish, both on small surfaces as well as large areas. For this reason, the cement tanks, walls, columns, circular tanks and foundations were carried out with this product, displaying its excellent results.

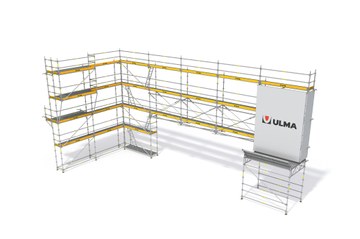

The BRIO system was used to assemble the working platforms at various heights with safety guardrail post and toe boards.