Description

Boasting a surface area of over 220,000 m² in the heart of the capital, the new shopping centre will house 220 businesses, including retail, recreation and dining, with parking for 2,000 vehicles and 82,000 m² of space available to rent for other uses. The project is being developed according to the BREEAM criteria for sustainable construction.

ULMA solution

The project design required solutions for slabs, columns, and drop beams. The quality of the slab finish is crucial for this type of construction, which is why the CC-4 System was combined with VR Tables for beams. Given the large obstacle free surface areas, 12,000m² of modular CC-4 formwork were provisioned.

This system, made of aluminium, allowed the formwork to be installed quickly in the spaces between the drop beams. The lightweight components make for quicker assembly and rendered cranes unnecessary. The formwork is ready to be stripped after three days, meaning that less material is required onsite. Not only that, but the system requires fewer props per square metre, facilitating transit and transportation under the slab. Efficient material reuse and rotation meant savings in cost, time, and space.

The drop beams, being uniform, were constructed using the most efficient system available: VR Tables. In order to optimise each pour, our engineering team developed a detailed plan including the optimal movement for each table, increasing speed and efficiency of the system even further.

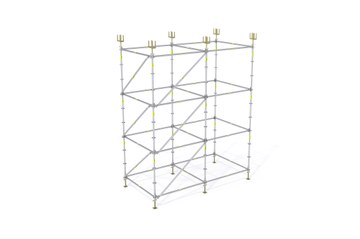

The flexibility of the modular BRIO and OC shoring systems made it possible to adapt to the varied height – ranging from seven to fifteen metres – and the distinct load-bearing requirements of the slabs, with respective thicknesses of 30 cm, 50 cm, and 100 cm.

The ORMA Formwork System, F4-MAX Articulated System for columns, and CLR Circular Formwork system were all employed for the building columns, according to the shape and thickness of the column required. The ORMA panels, were ideal for the 100 cm section columns ranging from 3.4 m to 7.2 m in height, without need for tie rods. CLR Circular Formwork demonstrated its efficacy in the construction of 90 cm diameter columns ranging from 4 m to 7 m in height. F4-MAX Formwork features fully integrated safety systems, including a platform and two access stairways. This minimised the need for portable stairways onsite and increased safety for operators.

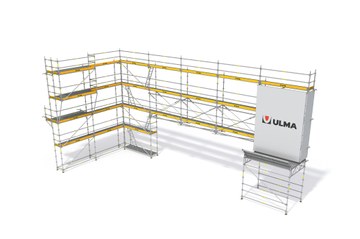

ULMA believes that increased safety means increased quality. That is why all of the systems used for this project feature fully integrated safety systems that ensure that all of the auxiliary work, including rebar placement and pouring, can be carried out in the safest manner possible. Moreover, the multidirectional BRIO scaffolding created safe working spaces, including accesses at height for both slabs and walls.