Description

The new headquarters of the Schlumberger industrial facility in Brazil stands out from its surroundings because of its imposing 2,500 m2 structure and 16 m high fair-faced concrete walls.

The administrative building, with four floors and a height of 4 m between floors, consists of two symmetrical lateral areas, of 26.4 m each, separated by a central area with two 13 m long walls.

ULMA Solution

For two-sided walls execution, ENKOFORM V-100 Formwork was used along with two-sided climbing brackets. Using this system, predefined patterns were carried out with 1 x 2.5 m boards, obtaining a perfect concrete finish. The lifting hook guaranteed safety while lifting the 5 x 4 meter gangs, during the entire process. Additionally, the working platforms created stable and safe areas.

The speed of assembly and disassembly, the ease of transferring the gang between the various uses and the safety achieved with the brackets, lifting accessories and the climbing ring, all proved that the ENKOFORM V-100 solution was ideal for the execution of this type of project.

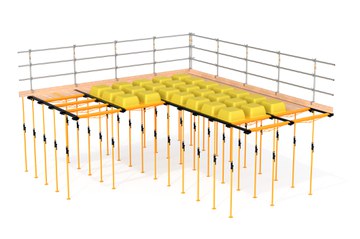

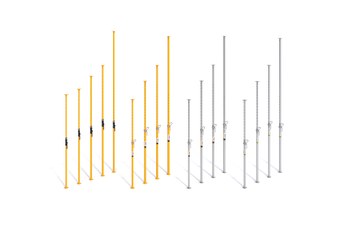

The construction work used the RECUB system, with a 12 cm rib, in order to complete more than 13,000 m2 of lightened slabs for the administrative building, the laboratory and the auxiliary structures. The SP Props were responsible for safely distributing the loads of the floors with a 4 m height. Additionally, the G Shoring System, in towers of up to 16 m in height, supported the cantilever beams that were placed on the edge of the façade.

The columns, interior walls, foundations, metallic structure bases, water tanks and other plumbing structures were executed with COMAIN system, which is light and handset, speeding up the work process.

The BRIO ladder provided safety and facilitated the vertical circulation of the workers during the entire project.