Description

Nye Veier is planning a new E6 from Kvithammar to Åsen in Stjørdal and Levanger municipality. The road is planned as a four-lane motorway with a speed limit of 110 km/h and will reduce travel time between Åsen and Stjørdal by 9 minutes.

The planning proposal is to turn the current two-lane road into a four-lane motorway. Its total length will be 19,8 km, 9 of them in Stjørdal municipality. Some of the most important structures that belong to the new E6 are Forbodsfjelltummelen (6080 m), Høghåmmårtunnelen (1360 m) and Vollselv bridges.

Vollselv bridges K101 and K102 will carry the E-6 over Vollselvdalen and Nordlandbanen. The bridges are approximately 350 m. long and have 10 variable spans. The distance between both structure will vary from 1,6 metres in the south to 5,2 metres in the north due to the adaptation to the tunnels that go through Forbordsfjellet.

The cross section of the bridges consist of prefabricated concrete beams and a superstructure that should be casted in place.

ULMA Solution

ULMA Construction has provided the design and solution for piers, pier heads and parapets for both bridges.

Piers

Both K101 and K102 have 11 axis, 2 abutments and 9 piers covering the total length of both decks. The height of the piers goes from 3 to 16 metres. The dimensions of the piers are 4.00 x 1.20 metres.

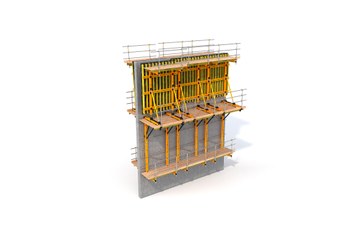

ULMA has supplied ORMA vertical formwork and BMK climbing system to cast all the piers. The standard pouring stage for the highest piers was 5.2 metres high.

Pier heads

The pier heads have a trapezoid shape. Their maximum thickness is 1.9 metres and a width of 1.2 as the dimension of the pier.

ULMA provided BMK climbing system around the piers. The brackets were supported in the last phase of every pier thanks to embedded anchorages, also supplied by ULMA. The vertical formwork was placed over BMK system.

For vertical faces, ORMA was choosen product. This modular formwork made the assembly easier and faster. In case of the lateral faces, because of their inclination, HMK formwork was supplied.

Parapet

The deck of both bridges was composed by prefabricated concrete beams between spans and a superstructure that was casted in place. Firstly, the concrete beams were placed over the pier heads. For that, workers had to access over there. ULMA supplied the solution for the working platforms. Afterwards, once all these prefabricated beams were positioned, ULMA designed and supplied short MK brackets to cast the parapet. These brackets were supported on anchorages that were embedded during the prefabrication of the lower beams.