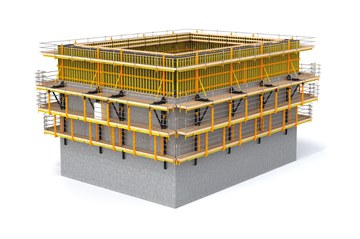

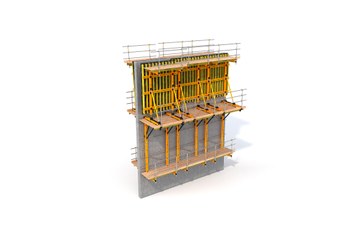

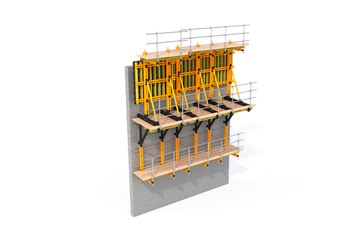

The V-100 ENKOFORM wall and column formwork offers great performance and excellent finishes to any vertical structure in building construction and civil works: walls, piers, abutments, columns, etc. The panels are shaped to measure according to needs.

- Shape: This system enables to assemble customized panels with the needed dimensions, always with standard components

- Size: panels can be assembled with the required height and width depending on the characteristics of the structure. The maximum panel size is 36 m2

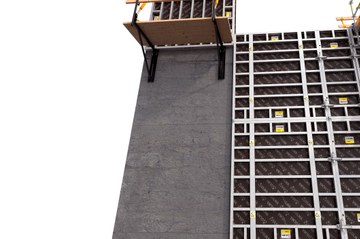

- Concrete finishing: excellent fair-faced concrete quality finishing in addition to predefined patterns can be obtained

- Concrete pressure: Depending on the required concrete pressure, panels configuration might be changed by modifying the distance between the timber beams and the walers

- Requires pre-assembly of panels (steel walers and timber beams which hold the plywood)

- Versatile and flexible for any geometry

- Excellent concrete finishing. Easy arrangement to obtain the wall pattern defined by the architect

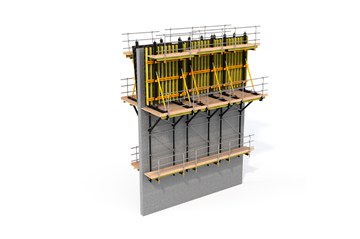

- Optimised formwork with regard to defined concrete pressure

- Easily replaceable plywood in case of damage

- Easy jointing of walers and timber beams

- Common standard accessories shared with other ULMA formwork systems: push-pull props, climbing brackets, anchors, etc.

- Lower transport volume when moving the items in dismantled state

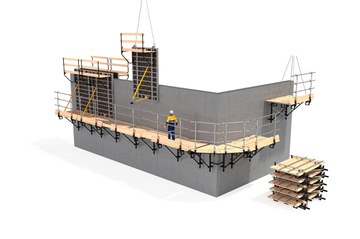

- Minimum number of fillers between panels

- Guaranteed safety. Easy-to-assemble safety items

- Simple and tight panel joints with panel connectors

- Exerts a correcting function by absorbing possible deviations during assembly

- Less panel edge damage due to the design of the Panel Connector and Pin (its conical part brings the panels closer together and its cylindrical part fixes their position)