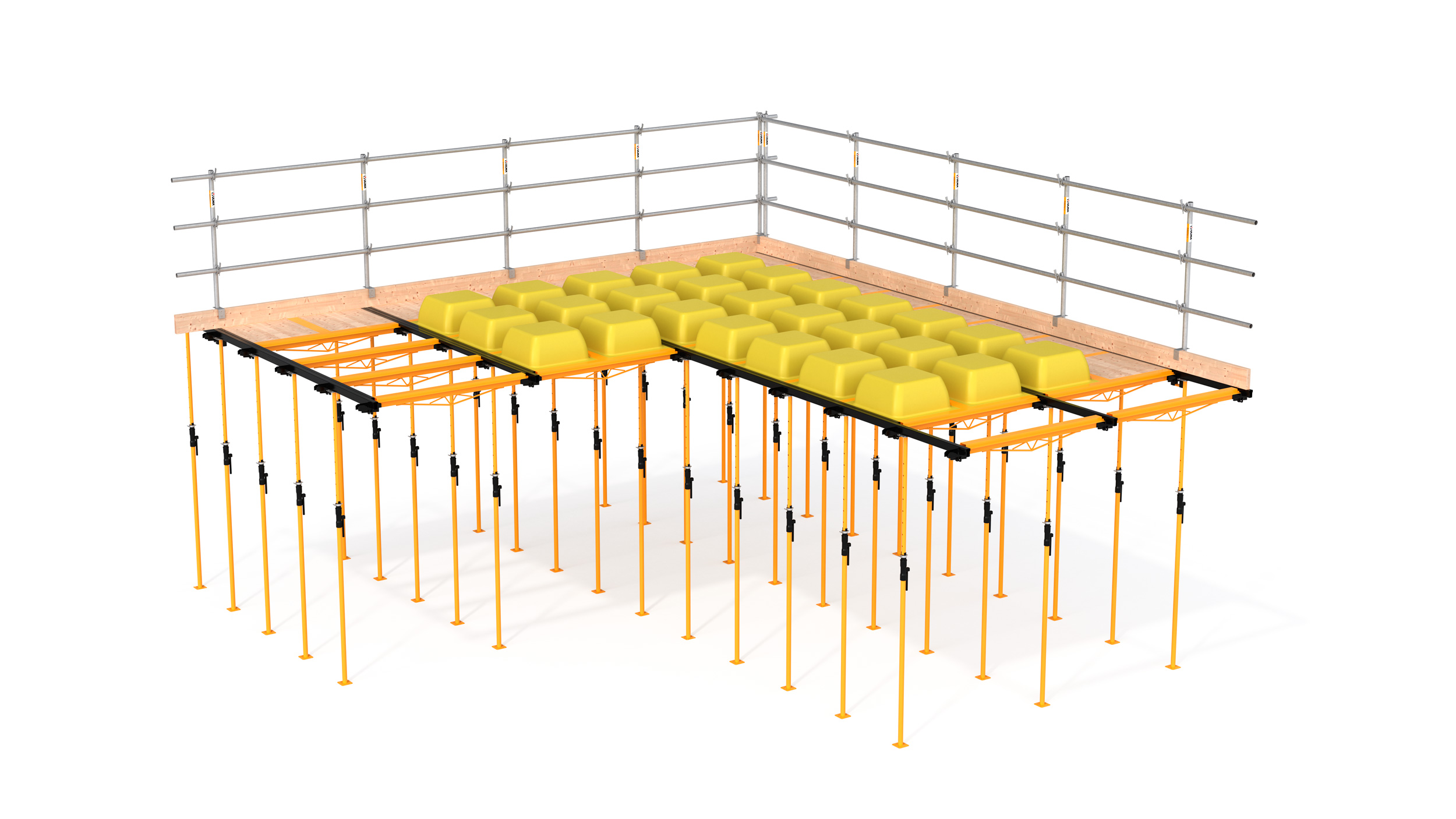

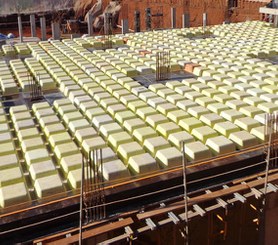

RECUB is a horizontal formwork for the construction of bi-directional reticular slabs with reusable box moulds (waffles).

With the same standard items, slabs with different rib widths can be built, according to the fire protection standard (12, 16 and 20 cm).

This modular formwork is mainly oriented towards non-residential construction and is ideal for car park construction.

Main features of reticular slabs compared to solid slabs:

- Eases large spans between piers. It also allows free and strategic positioning of the columns, which provides a great deal of flexibility for complex project solutions (openings, ramps, etc.)

- Withstands high live loads

- Consists of lightened areas and solid slab areas

- Quick and easy assembly

- The steel grid can be assembled previously to the placing of waffle moulds and plywood

- For erection, only hammer required

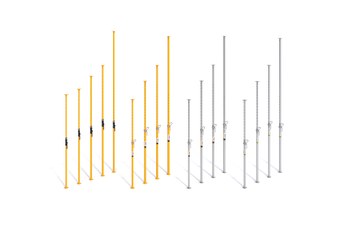

- Long-lasting heavy-duty design. Highly resistant steel structure with polyester resin coating

- Long-lasting waffle moulds, resisting damages and deformation

- Main beams and props (or shoring) make up the load-bearing structure of the system. The recoverable material can be retrieved after 3 days for the next pouring stage

- No re-propping nor prop moving until complete falsework removal

- High assembly efficiency. Trolleys or mobile towers for erection can be easily moved (large distance between props)

- Flexible system:

- Covers different geometries, with varying grid widths, several main beam lengths available

- Adapts to solid and lightened areas (plywood, waffle and half-waffle moulds)

- Perimeter solutions

- Formwork support with prop or shoring

- Safe system:

- Easy integration of perimeter and openings protection with handrails

- Waffle mould and board firmly fitted between main beam and secondary beam

- Net under formwork as safety item and for collective protection when assembling waffle moulds and plywood