The CC-4 is a recoverable modular aluminium formwork optimised for the construction of solid or lightened slabs with excellent concrete finishes. With an aluminium structure and a fast and effective stripping system, it is designed to obtain reductions in assembly and dismantling times with high safety standards guaranteed for the worker.

It also permits two types of assembly: with panel (aluminium frame with integrated board) or phenolic plywood.

- Two modes of assembly are possible, with panels or plywood:

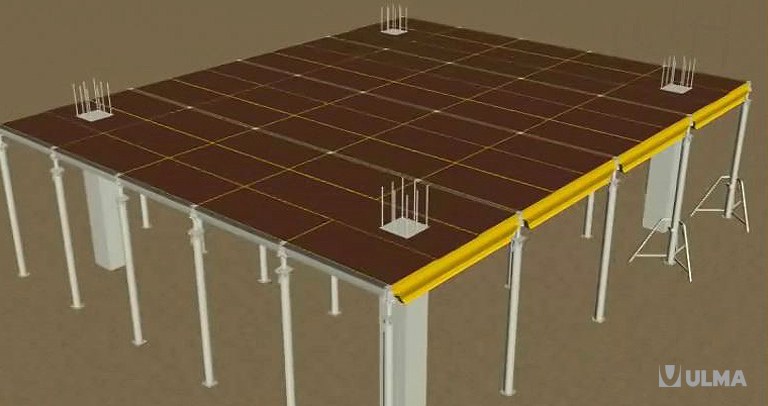

- CC-4 PANEL System

Is perfect for large slabs in building construction, with regular geometry and spans between columns, and high demands for finishing quality. Is consisting of dropheads CC, beams CC, transversals CC TE and panels.

Panels make up the biggest part of the form face. With the basic grid 2.32 m x 1.5 m, a prop rate of 0.29 props/m2 can be achieved.

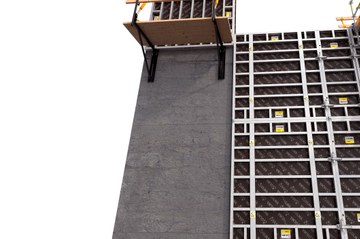

- CC-4 PLY System

It is designed for slabs of any kind of geometry and high demands on finishing quality. Is consisting of grid of dropheads CCT, beams CC, transversals CC TR and plywood. The dropheads allow recovering beams, transversals and plywood. Great flexibility.

- Safe stripping due to drop-down system to lower the formwork (drop distance 15 cm)

- Lightness: high assembly efficiency

- The formwork face provides superior concrete finishing

- Stripping and material retrieval without the risk of falls: highest worker’s protection

- Formwork retrievable in 3 days. Only the props with Dropheads CC remain as load-bearing items

- It allows the assembly of the grid previously to the placing of panels or plywood

- Great flexibility: it allows a change in beam direction, 90° assembly possible

- Efficient solutions for infillings on column and wall, perimeter protection and safety

- Slabs of up to 90 cm thickness, depending on grid size in use