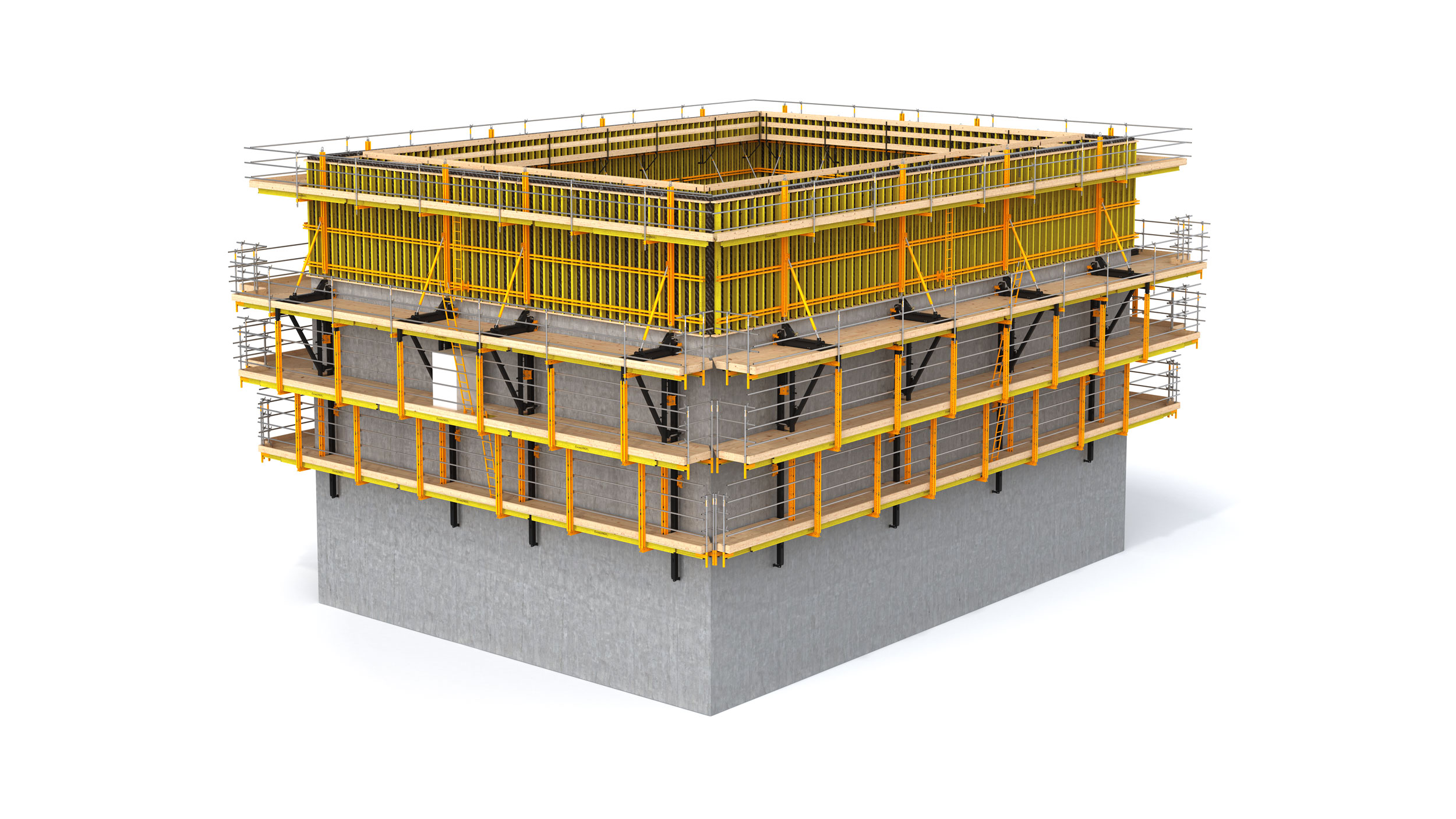

The ATR self climbing system is a formwork support structure for the construction of walls and other vertical structures without a crane (hydraulic and mechanical mechanisms).

The climbing process consists of the successive lifting of the mast and the climbing bracket-formwork-set erection along the wall surface.

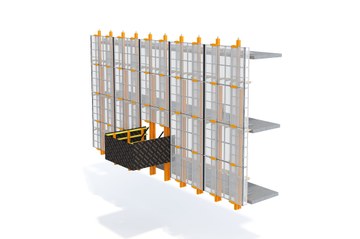

Self-climbing bracket ATR-B

Self-climbing bracket configuration where the formwork panel is stripped with roll-back carriages (2ft -3.5in) on the bracket itself. It is also equipped with components for horizontal and vertical plumbing and positioning of the formwork. It features two platforms: main working platform (8ft-2in) and control platform for the operation of the hydraulic system. Moreover, three optional platforms for pouring, items recovery and other tasks can be installed.

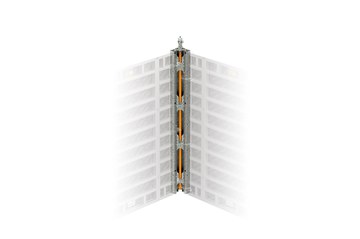

Self-climbing narrow bracket ATR-N

Used in narrow shafts between walls with widths of 5ft-9in to 8ft-2in where the ATR-B bracket cannot be used. The formwork hangs from an upper structure (outrigger) enabling stripping, retraction and positioning work.

Self-climbing platform ATR-P

Platforms used in shafts where for reasons of dimensions, loads or geometry, a platform system performs better than self-climbing brackets.

The structure is based on the MK System. It can adjust to different geometries and be fitted with different formwork systems (carriages or outrigger structures). Structures for the support of auxiliary elements such as concrete placing booms and small cranes can be attached to this system.

- Versatile for all types of requirements in the construction of high-rise buildings

- Easy to adapt due to MK System components: closures, installation of platforms, safety and cone recovery

- Less need for crane assistance. Formwork, working platforms and concrete placing boom can be simultaneous lifted

- Hydraulically operated: superior performance compared to conventional climbing with crane. Very fast construction pace

- Operates even in adverse weather conditions

- Safety in lifting and handling at great heights

- Adaptable to complex wall geometries

- Large and protected working platforms. Safe access

- High load capacity

- The working load of each cylinder can be controlled separately

- Hydraulic power unit operates up to 12 cylinders simultaneously. Large formwork sets can be easily lifted

- Climbing brackets are anchored to the wall with cones embedded in the concrete (absorption of horizontal and vertical loads)

- Roll-back carriages for work between formwork panels

- Main accessories are common throughout the product range

- Compatible with all vertical formwork systems and with MK System