Description

This terminal is located at Golding Point and within the Port of Gladstone.

With the growing demand for coal, WICET will provide a major impetus to the export volume of Queensland coal industry. On commissioning, the terminal will double the export capacity of the Port of Gladstone with up to 80 million tonnes per year.

ULMA Solution

ULMA supplied all the formwork and scaffolding required for the project, which included a 2 km long jetty conveyor and the construction of 950 m coal transport channels.

Many factors have been taken into account such as waterproofing, changes of direction and safety, the latter being vital in the project.

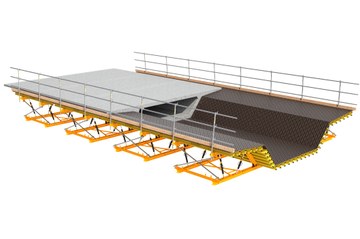

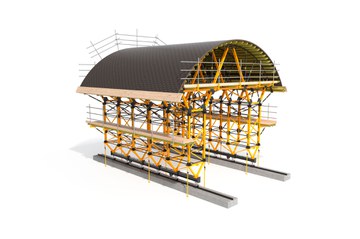

MK form carriers were used to meet all these requirements. Waler joints of the MK System provide high stiffness and require less material. Moreover, they enable the placing of larger pouring platforms than the usual ones.

The tunnels were built in variable lengths of 15 to 30 m to ease form carrier adaptation to the changes of direction and varying slope.

Its hydraulic system provided a smooth stripping, and the electric motors moved the form carriers at a speed of 6.2 m/minute. The inside diameter of the tunnels was 6.5 m with variable wall thickness between 37.5 cm at the top and 70 cm at the bottom of the side walls.

Moreover, ENKOFORM VMK and ORMA wall formwork and ENKOFLEX slab formwork has been supplied.

This Project has been carried out in collaboration with Uni-Span, our partner in Australia. For more information please visit Uni-Span’s website