Description

The construction of this tunnel, especially because of its width, has resulted in a significant improvement of the traffic circulation in the Pesaro area.

ULMA solution

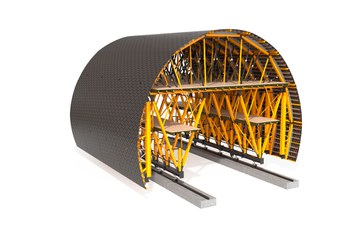

The reduced project time and the profitability of the project were achieved thanks to the use of MK Structures, which are versatile and have a high load bearing capacity. Their modular design and the correct combination of accessories enabled undertake any type of configuration.

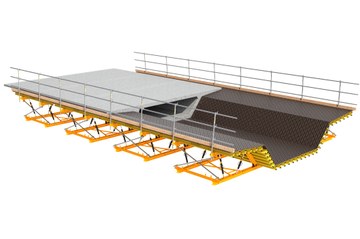

The formwork carrying trolley used to build the tunnel galleries (15.7 m wide, 6.2 m long and 9 m high) was made up of standard parts. Hydraulic jacks controlled from a central unit were in charge of putting the formwork panels in place and moving the structures inside the tunnel. This system made the task of moving the 28 t MK Structure easy. The vault formwork carried by the trolley was lifted by means of hydraulic cylinders.

The formwork modules were pre-assembled in the warehouse, and so only final adjustment was necessary on site. This was the way to reduce erection time and to ease the workers’ tasks. All construction stages were supervised by specialised staff.

The formwork carrying trolley was equipped with working platforms and safety handrails in such a way that all safety requirements were fulfilled at all times.