Description

The two towers, designed by the well known architect Toyo Ito, are approximately 120 m high. Each has its own function: one is a hotel and the other is a 40,000 m2 office building.

ULMA Solution

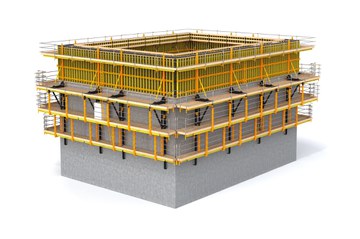

Since these are buildings of more than 120 m and approximately 28 floors, they required the use of a system able to perform the work at height quickly, safely, and with quality. For this reason, ULMA used the ATR Self-climbing System, from the underground floors to the upper levels. It is a conventional climbing system to which mechanical and hydraulic solutions are added to enable lifting the system without the use of a crane.

The peculiar silhouettes of both buildings required specific concrete cores. The core of the hotel building, with a cylindrical geometry, 13 m diameter and 40 cm wall thickness, was solved with an interior platform and outer brackets, both self-climbing. Moreover, the rotation effect was obtained with the variation of the surface from one floor to the other, from 700 to 1,000 m2. The rectangular geometry of the office building, with 45 cm wall thickness, was solved with three interior platforms and outer brackets, all self-climbing.

This system optimized its results with the combination of other products from the portfolio:

- Underground slabs: CC-4 system with ALUPROP Aluminum post shore.

- Above ground slabs: VR Table system and EP post shore.

- Interior core slabs: ENKOFLEX system and EP post shore.

- Columns: CLR vertical formwork, ORMA and COMAIN for interior core columns.

- Perimeter walls: ORMA vertical formwork and Single-sided Formwork Systems.

Thus, in the execution of concrete cores, it was possible to lift the formwork in adverse weather conditions. The system's productivity or profitability was always ensured, since the execution rate, in this case, was of an entire 700 - 1,300 m2 floor every 6 or 7 days. The self-climbing technique is based on a hydraulic system that allows the equipment to be lifted automatically and simultaneously with the successive movement of the formwork and the masts. This system, used along with ENKOFORM V-100, enabled the execution of walls with a height between slabs of 3.84 m in the hotel, and 4.14 m in the office building.

Safety is guaranteed throughout this entire climbing process. The working platforms are wide and protected from any external agent.

In order to optimise the execution of both buildings, the self climbing system also made it possible to lift auxiliary elements such as the placing boom, which is responsible for pouring the concrete of all the structural elements (walls, slabs, columns...). In this manner, the concrete was pumped from the ground floor to the floor being worked on, and poured by means of the placing boom.

Thus, in the execution of concrete cores, it was possible to lift the formwork in adverse weather conditions. The system's productivity or profitability was always ensured, since the execution rate, in this case, was of an entire 700 - 1,300 m2 floor every 6 or 7 days. The self-climbing technique is based on a hydraulic system that allows the equipment to be lifted automatically and simultaneously with the successive movement of the formwork and the masts. This system, used along with ENKOFORM V-100, enabled the execution of walls with a height between slabs of 3.84 m in the hotel, and 4.14 m in the office building. Safety is guaranteed throughout this entire climbing process. The working platforms are wide and protected from any external agent. In order to optimise the execution of both buildings, the self climbing system also made it possible to lift auxiliary elements such as the placing boom, which is responsible for pouring the concrete of all the structural elements (walls, slabs, columns...).In this manner, the concrete was pumped from the ground floor to the floor being worked on, and poured by means of the placing boom.

In the execution of the outside formwork of the office building, the ATR Self-climbing System was composed of brackets that supported the formwork, joined by means of a roll-back carriage. This system, controlled by a rack mechanism, separated the wall panels in the stripping stage. It also has a push-pull post shore that plumbs the formwork, as well as adjustment elements that enable to position it vertically and horizontally. On the other hand, the inside formwork was resolved with self-climbing platforms, composed of trusses. The four platforms that make up the system are communicated via ladders that make it possible to move through the structure with complete safety.

Given the curved geometry of the hotel, the outside formwork, supported on self-climbing brackets, was formed by a system of curved walers with the corresponding beams and phenolic plywood.The lifting was done, both in the interior and the exterior shafts, by means of two gangs controlled by two independent hydraulic power systems.