Description

This project is located in 262 Fifth Avenue and is a 54-story residential skyscraper in the NoMad neighborhood in Manhattan, New York City. Designed by Meganom with SLCE Architects as the executive architect and developed by Boris Kuzinez of Five Points Development under the Five Points 262 Project LLC, the 860-foot-tall structure will contain 41 condominium units. CM & Associates Construction Management is the general contractor for the property, which is located at the southwest corner of Fifth Avenue and West 29th Street.

The reinforced concrete superstructure has nearly doubled in height surpassing the parapets of its neighbors. Despite its slender profile, 262 Fifth Avenue will make a significant impact on the skyline, particularly when viewed from the south within the pedestrian plaza by the Flatiron Building and Madison Square Park. This spot had long offered a prime vantage point of the Empire State Building, which will eventually be obscured by the new skyscraper.

ULMA Solution

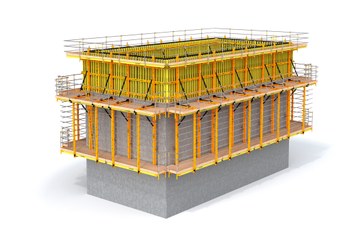

The customer, advised by the ULMA technical team, chose a portfolio of ULMA systems to form this unique structure. MEGALITE is being used to form the core walls, shear walls, and columns up to 12' to 16' high. MEGALITE is a vertical formwork system for handset and gang forming applications, utilizing quick connecting clamps to join panels together.

The slabs are being formed using the panelized CC4 shoring system that facilitates quicker, more efficient erection to support 24" slabs up to 16 ft in height that are found throughout the building. CC4 is light, safe panelized slab formwork with high productivity and excellent concrete finish. Perfect for solid or lightened slabs.

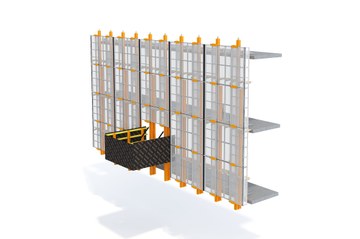

For wind protection, the technical solution provided by ULMA was the HWS system. This was used up to 60' in length, around the perimeter building and was a perfect solution to allow the customer to quickly lift and set the screens with the use of our hydraulic power units capable of lifting 2 screens at once.

The RKS system is a flexible rail-guided climbing formwork for forming cores, shear walls and perimeter walls using a hydraulic lifting mechanism. In this case the system was also utilized to form and climb the exterior face of the core walls with the same hydraulic power units.