Description:

351 Marin Blvd. is a mixed-use project located in the heart of downtown Jersey City in New Jersey. The tower will have 507 apartments, including 205 studios, 243 1-bedrooms, and 59 2-bedrooms units. Along with the residential units, the development spans around 8,000 ft2. of commercial space. Moreover, the building designed by Hollwich Kushner with HLW International includes two floors of amenities and a garage with up to 200 places.

The 38-story tower enjoys an excellent location. Jersey City is known for its vibrant culture and diversity, along with the magnificent views of the New York City skyline that can be seen in many parts of the city. The Downtown area is surrounded by top award-winning restaurants, cultural and artistic events such as the Historic Downtown Special Improvement District’s Groove on Grove, luxury living, and the quickest transportation to Manhattan by taking the train or ferry- a 15-minute commute to NYC.

ULMA Solution:

ULMA provided highly efficient solutions to ensure safety and performance savings on-site. For the construction of walls, we offered our handset panel formwork MEGALITE- the forming system was utilized at the ground floor for shear walls and to accommodate 9’-8” high and 12” thick walls. In this case, the MEGALITE system worked synergistically with ULMA’s shaft platform KSP, a simple solution that supports the inner core forms.

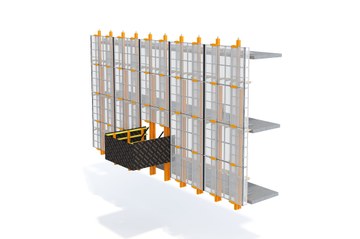

Additionally, ULMA provided a total of 30 HWS perimeter safety screens to cover part of the perimeter of the building. This system adds protection in three levels: the one being poured and the two below. The screens are specially designed for high-rise buildings- in this case, and a hydraulic self-climbing operation lifts the panels. The HWS system serves to protect workers from adverse weather conditions, and objects from falling from the edge of the slab, and to prevent pedestrians from falling debris. It also eliminates the visual effect of height for workers in the building. Telescopic screens are also part of the safety solution, standard telescopic windscreens consist of an 8’ wide base screen, with one or two telescopic panels on the sides, that can reach up to 12’-8” width, with both telescopic sides opened to their maximum extension.

The main structure of the windscreen is based on the MK system, which provides great versatility when configuring different types of structures, making the system easily adaptable to various elevations, sections, platform types, etc.

As a last solution, ULMA provided H20 beam slab formwork ENKOFLEX for shoring purposes. This system is adaptable to almost any type of slab and height configuration. It is easy and quick to erect and adds high concrete finishing requirements.