Description:

The 260,000 SF, 404-foot tall, 31-story mixed-use superstructure is located in Lower Manhattan. 185 Broadway was designed by FX Collaborative Architects and developed by SL Green. It is expected to have over 200 rental units, including studios, 1, 2, and 3-bedroom apartments. The structure will also include retail spaces and three floors of commercial space.

The new building is strategically located next to the recently renovated Fulton Street Subway Station and one block away from the World Trade Center. Rising above the city's financial heart, the tower will offer magnificent views of the skyscrapers. Residents and visitors will have a wide array of dining, entertainment, and fitness options available since it's close to renowned places such as the South Street Seaport, One World Observatory, TriBeCa, and various landmarks of New York City.

ULMA Solution:

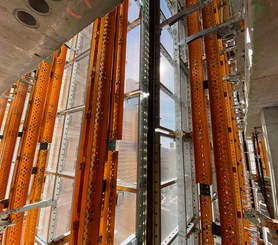

ULMA provided over 25 HWS Perimeter Safety Screens to cover the building's perimeter, ensuring the safety of both workers and pedestrians during the construction of the superstructure. The system offers protection in four levels: the level being poured, and the previous three. Additionally, the self-climbing system ensures excellent protection against weather, reduces the visual height effect, and it is highly versatile since it can be easily adapted to different geometries.

The screens were installed by crane and then lifted using the hydraulic system. The recently launched telescopic screens were used in this project; these screens are formed by two masts that serve as support to the HWS panels connected by the mast-panel joint. All the screens arrived in pre-assembled condition at the job site. Standard telescopic screens consist of an 8' wide fix screen with one or two telescopic panels on the sides that can be opened up to around 12' -8" on site.

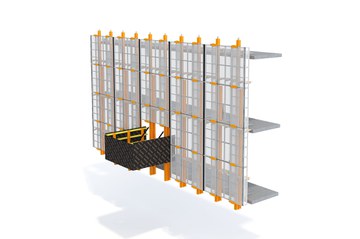

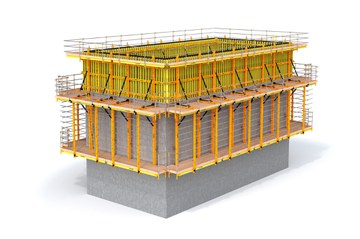

The technical solution provided by ULMA for the climbing system, Rail Climbing Formwork RKS for the southwest part of the building, consisted of four platforms. The primary purpose of the RKS platform is to serve as a support for the forms, the working platforms, and the live load. The shear walls' RKS section has four levels of platforms: pouring, main, control, and trailing.

· Pouring platform: Used for concrete pouring and anchorage positioning.

· Main platform: Used as a passage to strip, to approach, and to plumb the formwork panels. By using the roll-back carriage MK-120 system, steel reinforcement work and panel cleaning can be carried out from this platform.

· Control platform: Used to access the climbing heads and to operate the hydraulic cylinders. The hydraulic power unit rests on this level. Typically, the elevation of the system is controlled by this platform.

· Trailing platform: Used to retrieve anchorage.